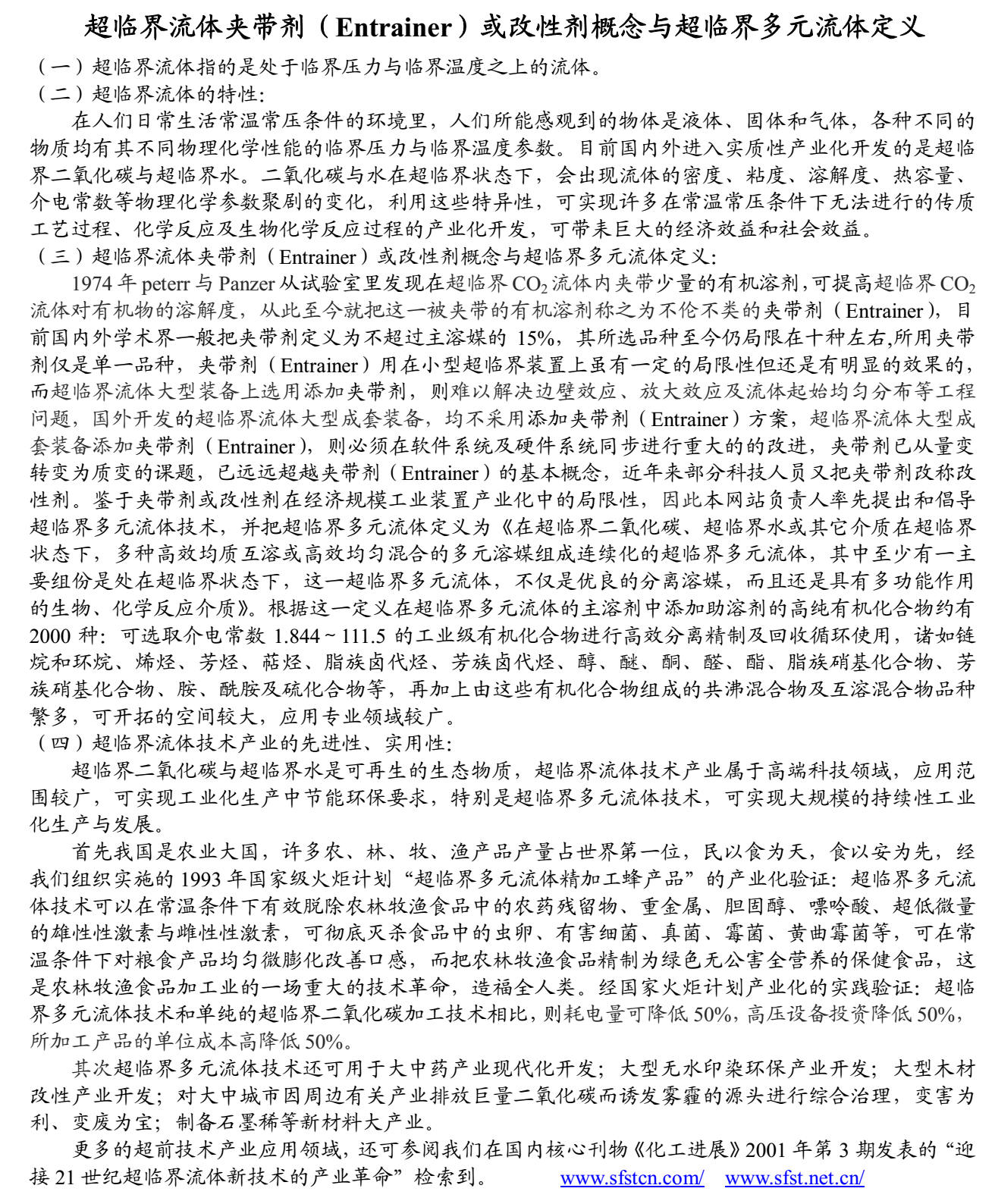

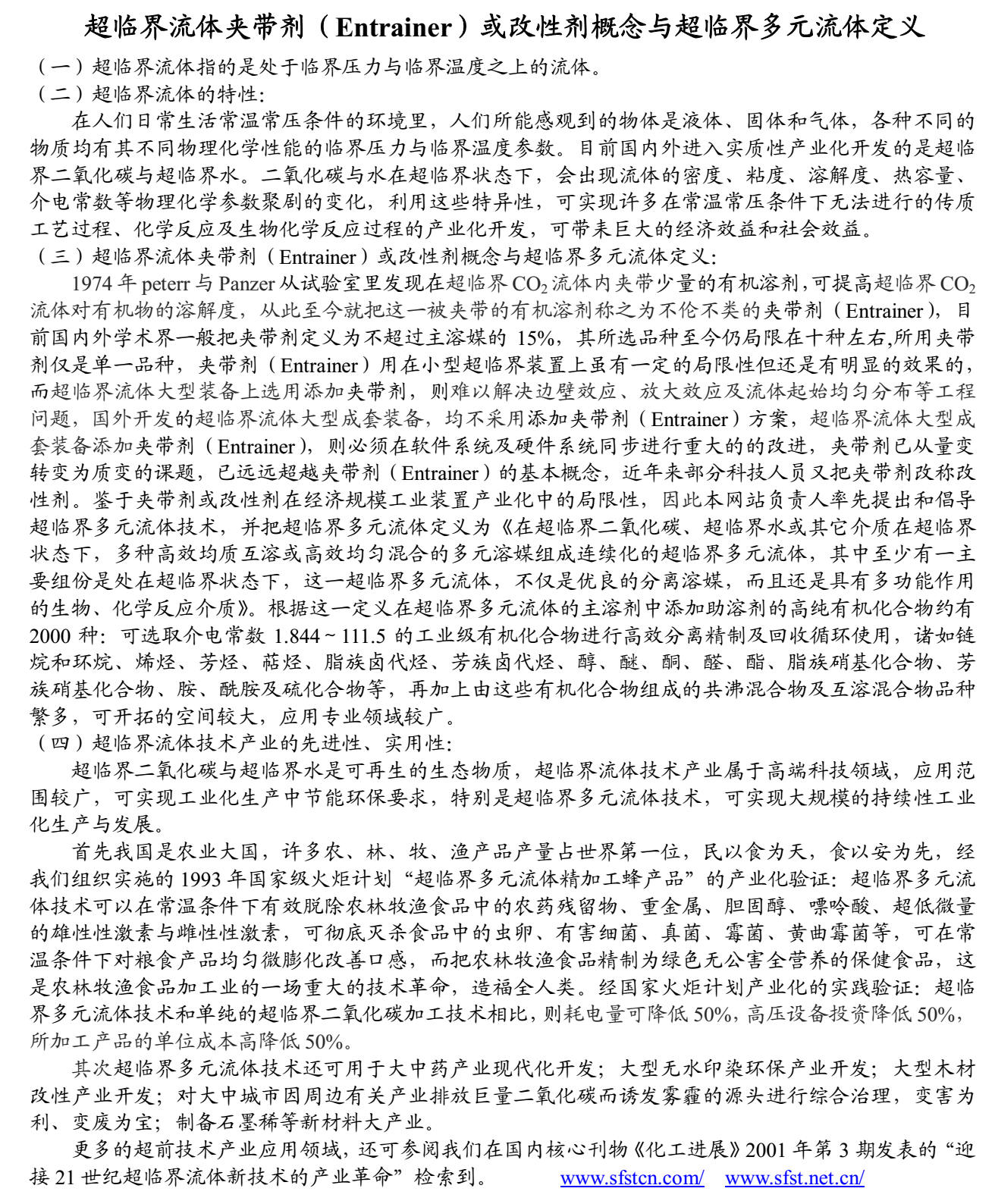

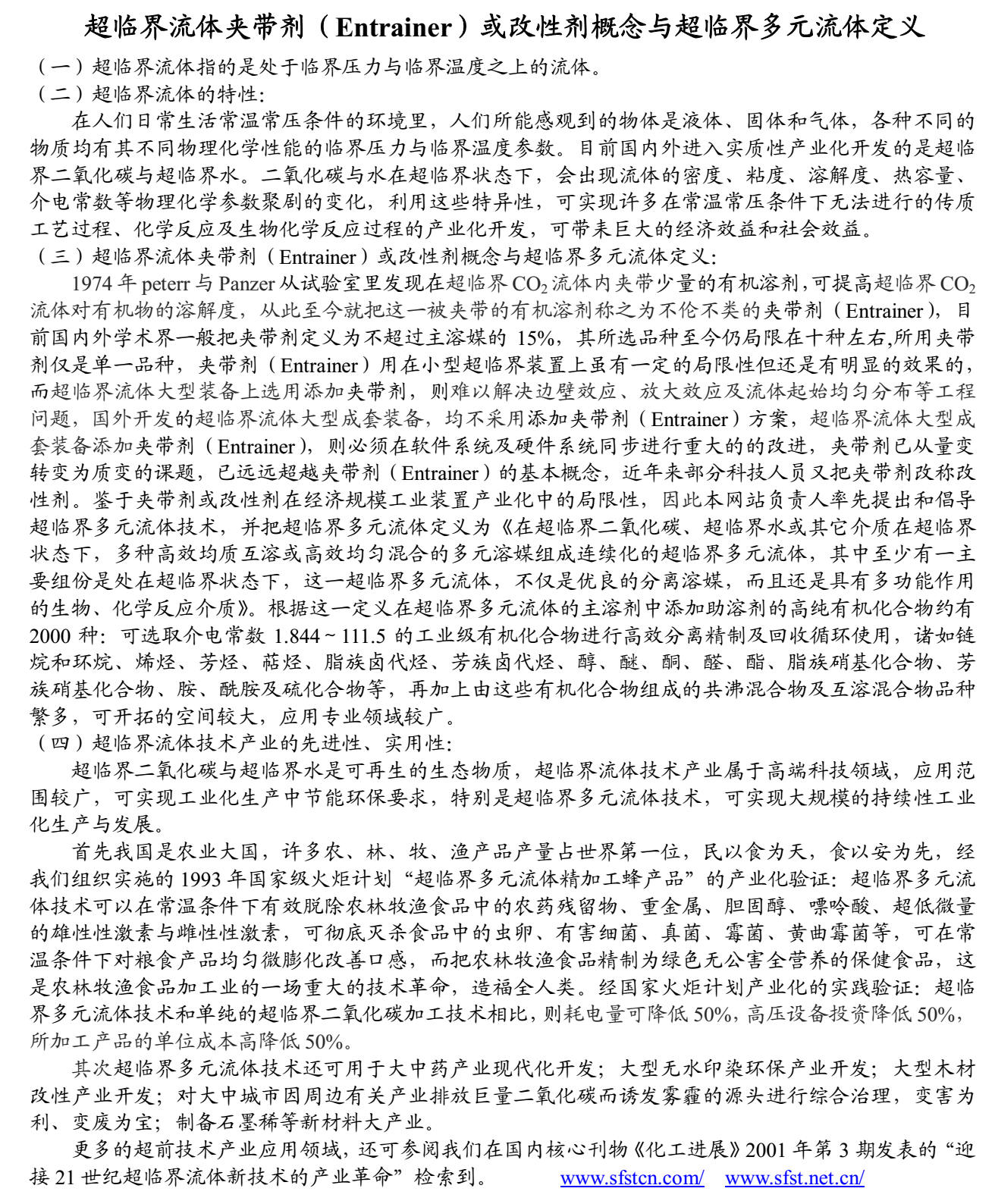

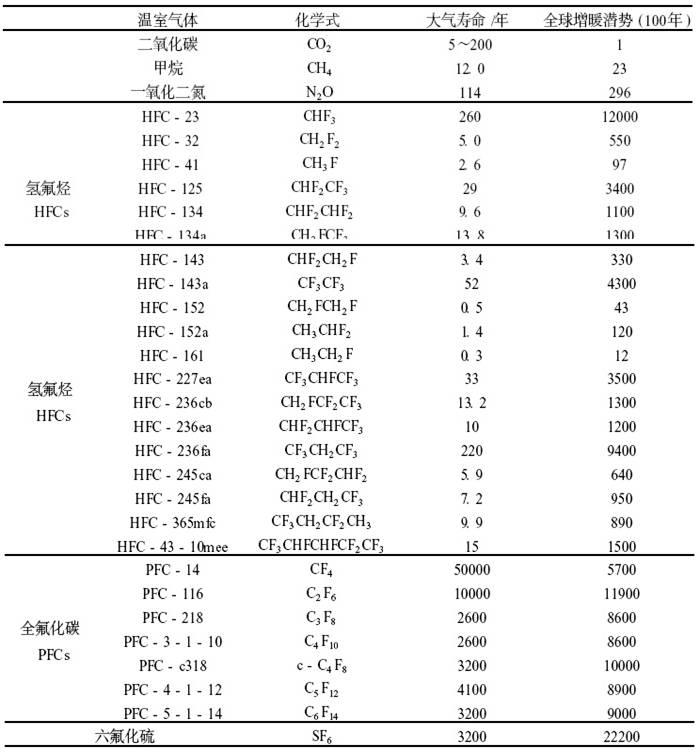

《京都议定书》要减排哪些温室气体

|

|

悄然兴起的亚临界萃取中的液化石油气、

丙烷、二甲醚、四氟乙烷、六氟化硫萃取剂令业内人士担忧

http://www.sfst.net.cn 编辑部稿

在防火防爆类的工厂设计规范中明文规定,凡是闪点<28℃的易燃液体,凡是爆炸下限<10%的可燃性气体均应列为甲级(最高级)防火防爆等级,而目前在国內悄然兴起的亚临界萃取中,个別企业却选用闪点及爆炸下限均远远低于这两个指标的

LPG(液化石油气)、DME(二甲醚)、丙烷、R600a(高纯度异丁烷)等易燃易爆危险品,用作亚临界萃取的主溶媒,其用于固体物料的间隙式萃取,由于要频繁的装卸物料需不断的打开

、关闭萃取槽顶盖,易燃易爆气体的洩漏在所难免,同时在频繁打开 、关闭萃取槽顶盖的过程中,产生静电火花的概率也较高,在规模化的工业生产中使用这些气体,危险性是显而易见的。

在连续密闭的大规模化的生产

LPG(液化石油气)、DME(二甲醚)、丙烷、R600a(高纯度异丁烷)等

的易燃易爆气体时,相对而言由于是在连续全密闭的条件下进行操作则较为安全。

而R134a(1,1,1,2-四氟乙烷)

的亚临界萃取,由于R134a是温室气体,它能阻挡红外辐射能返回天空,对全球气候变暖直接影响较大,其全球温室效应潜能值GWP高达1300。因此早在1997年12月11日联合国气候变化框架公约缔约国第三次会议通过的《京都议定书》中,R134a是明确规定要控制与削减排放量的六

类温室气体中的一种,其排放(散发)、使用、生产也将受到严格的国际管制。再者工业级R134a的单价高于食品级二氧化碳50倍以上,作为萃取剂使用,生产成本偏高,这也是工业化生产中企业难以接受的。

更有甚者,全氟化碳PFC(如CF4和C2F6)和六氟化硫SF6也是人为产生的气体,它们大气寿命非常长,对红外辐射有强吸收。所以这些化合物虽然排放量较小,但对未来气候的影响很大。CF4在大气中可以至少存留50000年。它有自然源,但目前的人为排放是自然源的1000多倍,并且是观测到浓度增加的主要原因。一个SF6分子的温室效应是一个CO2分子的22200倍。虽然它目前的大气浓度较低(4.2×10-12),但它的增长速率明显(0.24×10-12/年)。观测到的SF6增长率与根据销售和储存数据而计算所得的排放十分一致。

[200820053135.4]超声强化超临界或亚临界流体萃取装置

[200620009043.7]亚临界汽水两相流量计

[200520021800.8]亚临界空冷汽轮机

[200710032663.1]天然产物有效成分的超声强化亚临界水萃取方法及装置

[200810088744.8]多功能亚临界压力蒸气缸

[200610104744.3]亚临界流体萃取溶剂及萃取方法/其主要特点是以液态六氟化硫为萃取溶剂/2008.04.16公开

[200610010985.1]玫瑰精油真空水散冲蒸亚临界萃取技术/2008.01.02公开

[200610081101.1]亚临界二甲醚流体提取天然除虫菊素的方法/2007.11.28公开

[200620009043.7]

亚临界汽水两相流量计/2007.10.03公开

[200610114603.X]超或亚临界下有机胺和环氧丙烷催化制备生物柴油的方法/2007.05.30公开

[200580004805.2]亚临界水分解处理物的生产方法及亚临界水分解处理物生产装置/2007.02.21公开

[200610010882.5]一种亚临界—超临界流体转化制备生物柴油的方法/2006.10.11公开

[200510061998.7]亚临界水提取中药丹参中脂溶性成分的方法/2006.08.23公开

[200510022594.7]亚临界复合热载体发生器的高温高压燃烧系统/2006.07.19公开

[200510012660.2]亚临界甲醇相固体酸碱催化油脂酯交换制生物柴油的方法/2006.01.11公开

[200310109657.3]一种低阶煤在亚临界或超临界水中连续转化的方法/2004.11.10公开

[200610070495.0]一种低压超临界萃取工艺及其装置*/本专利以1,1,1,2-四氟乙烷(R134a)作为亚临界流体萃取剂,萃取温度30~60℃萃取压力0.8~8NPa[编者按R134a:Tc:101℃;Pc:0.4MPa;其全球温室效应潜能值GWP高达1300,一些国家已禁止使用]

[200610048835.X]一种提取油脂的方法*/本专利以DME作为亚临界流体萃取剂,萃取温度30~90℃萃取压力0.5~3MPa[编者按DME:Tc:127.228℃;Pc:5.3558MPa;闪点

-41℃存在安全隐患等诸多问题]

[ 200510048681 ]-青蒿素提取的方法*

/本专利以DME作为亚临界流体萃取剂,提取温度20~60℃提取压力0.5~3MPa[编者按DME:Tc:127.228℃;Pc:5.3558MPa;闪点

-41℃存在安全隐患等诸多问题]

[ 200510048619 ]-亚临界流体处理烟草的方法*

/本专利以DME作为亚临界流体萃取剂,萃取温度20~90℃萃取压力0.5~3MPa[编者按DME:Tc:127.228℃;Pc:5.3558MPa;闪点

-41℃存在安全隐患等诸多问题]

[200410022307.8]亚临界DME精制废弃烟草初提物的方法/

2005.10.19公开/本专利以DME作为亚临界流体萃取剂,萃取温度10~60℃萃取压力0.1~1.5MPa[编者按DME:Tc:127.228℃;Pc:5.3558MPa;闪点

-41℃存在安全隐患等诸多问题,而在萃取温度10~60℃萃取压力0.1~1.5MPa的气态DME状况条件下怎能具有萃取功能?而气态DME又怎么能称之为亚临界DME?]

[200410022306.3]亚临界DME萃取废弃烟草的方法/

2005.10.19公开/本专利以DME作为亚临界流体萃取剂,萃取温度30~90℃萃取压力0.5~3MPa[编者按DME:Tc:127.228℃;Pc:5.3558MPa;闪点

-41℃存在安全隐患等诸多问题]

[ 02134162 ]-除虫菊酯精制方法*

[ 02133470 ]-印楝油提取工艺

*

[ 01108701 ]-亚临界液化石油气萃取除虫菊酯的方法*

[200810072912

]-一种生产异构化啤酒花浸膏的方法

[ 200810040260 ]-一种超高参数湿冷汽轮机

[ 200810088744 ]-多功能亚临界压力蒸气缸

[ 200810015683 ]-一种合成YAG单晶纳米粉末的方法

[ 200810085141 ]-多功能高压蒸汽仓

[ 200810019214 ]-一种酚类化合物的同步净化提取方法

[ 200720099281 ]-自然工质制冷热泵装置

[ 200710032663 ]-天然产物有效成分的超声强化亚临界水萃取方法及装置

[ 200710194357 ]-多功能中压蒸气仓

[ 200710194355 ]-多功能高压蒸气储存仓

[ 200720117563 ]-一种大型全转速汽轮机中压缸叶片使用的纵树型P叶根

[ 200720117560 ]-一种大型全转速汽轮机中压缸叶片使用的纵树型P叶根

[ 200720117568 ]-一种大型全转速汽轮机中压缸叶片使用的纵树型P叶根

[ 200710305191 ]-具有热控制安全功能的制冷或热泵回路用恒温膨胀阀

[ 200710164338 ]-亚临界压力注汽锅炉

[ 200720175748 ]-亚临界压力注汽锅炉

[ 200710113212 ]-一种耐腐蚀防堵塞的超临界水氧化反应器

[ 200710113809 ]-一种制备富含多不饱和脂肪酸的甘油酯的工艺

[ 200710049980 ]-汽轮机末级长叶片用钢材料及其热处理工艺

[ 200710066167 ]-高压流体转化技术制备生物燃料的工艺

[ 200720038457 ]-一种连通器式汽包水位取样测量装置

[ 200710025027 ]-连通器式汽包水位取样测量装置及其几何尺寸的确定方法

[ 200710049323 ]-辣椒、薯类中有效成份的提取方法

[ 200710041319 ]-热塑性淀粉及其制备方法

[ 200710098995 ]-负载型单金属加氢催化剂的水热沉积制备方法

[ 200710048828 ]-一种超超临界强化流体传热方法及传热介质

[ 200710048834 ]-一种超临界热波传热元件及其工作介质灌装密闭方法

[ 200710109730 ]-调色剂及制备方法、显影剂、成像方法和装置及处理盒

[ 200610171462 ]-反应生成物的制造方法

[ 200610114603 ]-超或亚临界下有机胺和环氧丙烷催化制备生物柴油的方法

[ 200620125242 ]-汽包水位单筒式高精度电极测量筒

[ 200620009043 ]-亚临界汽水两相流量计

[200610104744.3]亚临界流体萃取溶剂及萃取方法/其主要特点是以液态六氟化硫为萃取溶剂/2008.04.16公开

[ 200710025027 ]-连通器式汽包水位取样测量装置及其几何尺寸的确定方法

[ 200710049323 ]-辣椒、薯类中有效成份的提取方法

[ 200710109730 ]-调色剂及制备方法、显影剂、成像方法和装置及处理盒

[ 200610171462 ]-反应生成物的制造方法

[

200610010985 ]-玫瑰精油真空水散冲蒸亚临界萃取技术

[ 200610114603 ]-超或亚临界下有机胺和环氧丙烷催化制备生物柴油的方法

[

200610088092 ]-一种萃取新鲜柚子花芳香性物质的方法

[

200610035905 ]-高含量共轭不饱和三烯酸石榴籽油的制备方法

[

200610010882 ]-一种亚临界—超临界流体转化制备生物柴油的方法

[

200610010808 ]-一种便捷有效的莽草酸生产方法

[

200510022594 ]-亚临界复合热载体发生器的高温高压燃烧系统

[

200510048737 ]-天然除虫菊素水乳剂及其制备方法

[

200510061998 ]-亚临界水提取中药丹参中脂溶性成分的方法

[

200510048681 ]-青蒿素提取的方法

[

200520022024 ]-三缸超临界空冷汽轮机

[

200510048619 ]-亚临界流体处理烟草的方法

[

200510118684 ]-确定半导体制造过程的独立式结构的线宽的系统和方法

[

200520021800 ]-亚临界空冷汽轮机

[

200520021745 ]-一种大型全转速汽轮机次末级叶片

[

200510094726 ]-汽包水位大量限全工况高精度电极传感器系统

[

200510021382 ]-汽轮机末级动叶片

[

200510028318 ]-亚临界汽轮机螺栓钢细晶粒处理工艺方法

[

200510084304 ]-清洗方法及用于实施该方法的清洗装置

[

200510012660 ]-亚临界甲醇相固体酸碱催化油脂酯交换制生物柴油的方法

[

200580018196 ]-烟提取物的制备

[

200580017005 ]-二氧化碳的分解方法和碳颗粒结构体的形成方法

[

200520018534 ]-空气灭菌除臭器

[

200580015823 ]-谐振功率变换器的备用运行

[

200580009279 ]-塑料的分解方法

[

200510018433 ]-一种用于果蔬中农药残留分析的样品预处理方法和装置

[

200510052653 ]-药剂含浸方法

[

200580004805 ]-亚临界水分解处理物的生产方法及亚临界水分解处理物生产装置

[

200580004599 ]-CO*存在下的电镀

[

200580004733 ]-聚碳酸酯的分解方法

[

200510011254 ]-用于跨临界CO*制冷循环的微通道板翅式内部换热器

[

200480034060 ]-聚合物及聚合物的制造方法

[

200410095437 ]-使用致密加工流体和超声波能处理半导体元件的方法

[

200480038727 ]-活性聚合物挤出物的制备

[

200410056082 ]-脂肪酸脂的制造方法

[

200410055063 ]-含有有机物的废水的净化处理方法

[

200410022306 ]-亚临界DME萃取废弃烟草的方法

[

200410022307 ]-亚临界DME精制废弃烟草初提物的方法

[

200410035253 ]-纳米碳材料的制备方法

[

200510127455 ]-生产乙酸纤维素的方法及其植物组分提取装置

[

200410008917 ]-制造纤维素模塑件的法,植物组分提取装置,和生产乙酸纤维素的方法

[

200510127454 ]-植物组分提取装置

[

200410016559 ]-二氧化碳电冰箱

[

200410055087 ]-制造纳米碳材料的方法

[ 03801005 ]-聚合物的制造方法

[ 200380110258 ]-树脂微粒的制造方法和树脂微粒

[

200310109657 ]-一种低阶煤在亚临界或超临界水中连续转化的方法

[

200380102845 ]-聚合物的分解方法

[

200380101897 ]-甲烷气的制造方法

[

200310107844 ]-超临界空冷汽轮机

[

200310107845 ]-超超临界空冷汽轮机

[ 03817167

]-烟草中成分的减少

[ 03820704

]-颜料纳米粒子的新型制造方法

[ 02134162

]-除虫菊酯精制方法

[ 02158446 ]-富勒烯的制备方法

[ 02154271

]-纳米碳材料的制备方法

[ 02126631

]-亚临界转速球磨机

[ 02274303

]-生产脂质体的设备

[ 02132650

]-脂质体的生产工艺及设备

[ 02133470

]-印楝油提取工艺

[ 02801115

]-用喷射临界状态的水来运行内燃机的方法

[ 02806085

]-利用超临界流体或亚临界流体的有机物质等的反应装置

[ 01815350

]-水热氧化处理废物的方法

[ 01108701

]-亚临界液化石油气萃取除虫菊酯的方法

[ 01206543

]-大型汽轮机新型末级叶片

[ 01122803

]-硬质聚氨酯泡沫塑料的原料制造方法,冷藏库的制造方法和冷藏库

[ 01113903

]-在亚临界状态下用CO*从银杏叶中萃取黄酮和萜类的方法

[ 00268712

]-采用波纹管的超临界水氧化法污水处理反应器

[ 00221057

]-汽包水位高精度取样电极传感器

[ 00100676

]-异物除去法及膜形成方法

[ 99123246

]-与布线亚临界接触的自对准工艺

[ 98117610

]-废弃物处理方法和废弃物处理装置

[

200510075433 ]-废弃物处理方法和废弃物处理装置

[ 98806386

]-在超临界流体中制得的生物功能聚合物

[ 98101649

]-缓和热转化--溶剂脱沥青组合工艺

[ 98804492

]-超临界反应装置及其方法

[ 98106777

]-一种费一托合成催化剂的原位再生法

[ 97198781

]-一种粉末状制剂的制备工艺

[ 97116908

]-多元高铬铸钢轧钢机组合式导板及其制造方法

[ 97225687

]-具有亚临界叶型的离心式前、后向叶轮

[ 97225208

]-无盲区云母双色水位计

[ 97217502

]-板式云母双色水位计

[ 96198262

]-制备丙烯均聚物或共聚物的方法

[ 96102285

]-蒸汽发生装置

[ 96107763

]-燃烧室

[ 96195038

]-环滚研磨机

[ 96194418

]-计量喷雾阀

[ 96192192

]-改性气凝胶的制备方法及其应用

[ 95242232

]-涡流式超临界、亚临界气体萃取装置

[ 94238937 ]-适用于任何工况的差压式水位测量元件

[ 94102373

]-一种γ-Fe2O3磁粉的制备方法

[ 94110049

]-耐低温可焊接细晶粒厚度方向钢板

[ 90106041

]-板式云母双色水位计

[ 90218673

]-具有亚临界叶型的离心式后向叶轮

[ 90100948

]-溶剂萃取方法

[ 88103142

]-双色照明双色液位计的双色照明方法和这种双色液位计

[ 87209305

]-扣合内通道式窥视镜体液位计

[ 86202977

]-一种反射.透射式双色液位计

Subcritical

Subcritical water chromatography: A green approach to

high-temperature liquid chromatography.

At

temperatures and pressures lower than 374 degrees C and

218 atm, subcritical water has widely tunable properties

such as dielectric constant, surface tension, viscosity,

and dissociation constant achieved by simply adjusting

the temperature with a moderate pressure to keep water

in the liquid state. At elevated temperatures, water

acts like a weak polar organic solvent. Thus,

subcritical water has been used as a green eluent to

replace hazardous solvents commonly used as organic

modifiers in RPLC. Subcritical water chromatography (SBWC)

is capable of separating polar, moderately polar, and

even some nonpolar analytes. Most of these low molecular

weight solutes are stable at elevated temperatures

during a chromatographic run. Some new packing materials

are also quite stable and robust at mild temperatures

ranging from 80 to 150 degrees C. Advantages of SBWC

include the elimination of hazardous organic solvents

used in traditional RPLC, rapid analysis time, improved

selectivity, temperature-dependent separation

efficiency, temperature-programmed elution, and

compatibility with both gas- and liquid-phase detectors.

In this paper, the technical aspects as well as the

applications of SBWC are reviewed. Topics addressed in

this review include the unique characteristics of

subcritical water, analytes separated by SBWC, packing

materials tested for SBWC, the application of GC and LC

detection techniques in SBWC, SBWC instrumentation

development, temperature effects on SBWC separation, and

models developed for separation in SBWC.

Rapid column heating method for subcritical water

chromatography.

A novel

resistive heating method is presented for subcritical

water chromatography (SWC) that provides higher column

heating rates than those conventionally obtained from

temperature-programmed gas chromatography (GC)

convection ovens. Since the polarity of water reduces

dramatically with increasing temperature, SWC employs

column heating to achieve gradient elution. As such, the

rate at which the mobile phase is heated directly

impacts the magnitude of such gradients applied in SWC.

Data from the current study demonstrate that the maximum

column heating rate attainable in a typical SWC

apparatus (i.e. using a GC convection oven) is around 10

degrees C/min, even at instrument oven settings of over

three times this value. Conversely, by wrapping the

separation column with ceramic insulation and a

resistively heated wire, the column heating rates are

increased five-fold. As a result, elution times can be

greatly decreased in SWC employing gradients.

Separations of standard alcohol test mixtures

demonstrate that the retention time of the latest

eluting component decreases by 35 to 50% using the

prototype method. Additionally, solute retention times

in this mode deviate by less than 1% RSD over several

trials, which compares very well to those obtained using

a conventional GC convection oven. Results suggest that

the developed method can be a useful alternative heating

technique in SWC.

Hydrolysis kinetics of trisaccharides consisting of

glucose, galactose, and fructose residues in subcritical

water.

The

hydrolysis kinetics of trisaccharides consisting of

glucose, galactose, and fructose residues with different

glycosidic bonds, 1-kestose, d-melezitose, d-raffinose,

and lactosucrose, in subcritical water were conducted

over the temperature range of 150-230 degrees C and at a

constant pressure of 10 MPa. The hydrolysis of

trisaccharides in subcritical water proceeded

consecutively, i.e., one cleavage of the two bonds

antedated the other. The preceding cleavage was not

expressed by the first-order kinetics, but by the

kinetics considering the concentration of the acidic

compounds, which were produced by the degradation of the

constituent monosaccharides. The hydrolysis of the

constituent disaccharides, except sucrose composed of

the alpha-Glc-(1-->2)-beta-Fru bond, obeyed first-order

kinetics. All of the rate constants of the hydrolytic

kinetics were determined, and the values were found to

depend on the type of bond.

Subcritical water extraction of nutraceuticals with

antioxidant activity from oregano. Chemical and

functional characterization.

In the

present work, oregano leaves (Origanum vulgare L.) are

explored as natural source of nutraceuticals with

antioxidant activity. To do this, subcritical water

extraction (SWE), a new environmentally friendly

technique, is employed as extraction procedure and HPLC

coupled to DAD is used for the chemical characterization

of the extracts. Moreover, the radical scavenging

1,1-diphenyl-2-picrylhydrazyl (DPPH) method and the

determination of the total phenolic content (measured

with the Folin test) are applied to evaluate the

antioxidant activity of the extracts. The extraction of

antioxidants from oregano leaves by SWE is studied

considering different temperatures (25, 50, 100, 150 and

200 degrees C) to investigate the selectivity of the

process. The highest antioxidant activity is observed

for the extract obtained at the highest temperature, 200

degrees C (EC(50) equal to 10 microg/ml). Moreover, the

extraction yield was also the highest (54% dry weight)

at these extraction conditions. The total phenolic

content showed no differences among the different

extracts, concluding that the amount of phenolic

compounds extracted was similar but the type and

structure of the phenolics was different, providing in

this way different antioxidant activity. Some compounds

could be tentatively identified, proposing some probable

chemical structures for some of them, such as flavanones,

dihydroflavonols, favonols and flavones.

Development of pressurized subcritical water extraction

combined with stir bar sorptive extraction for the

analysis of organochlorine pesticides and chlorobenzenes

in soils.

An

analytical method for the determination of several

organochlorine pesticides (OCPs) like

hexachlorocyclohexanes (HCHs), cyclodiene derivates (dieldrin,

aldrin, endrin, heptachlor, heptachlor epoxide, endrin

aldehyde, endosulfan and ensodulfan sulphate) and DDX

compounds (p,p'-DDE, p,p'-DDD and p,p'-DDT) as well as

chlorobenzenes in soils has been developed. The

procedure is based on pressurized subcritical water

extraction (PSWE) followed by stir bar sorptive

extraction (SBSE) and subsequent thermodesorption-gas

chromatography/mass spectrometry analysis. Significant

PSWE and SBSE parameters were optimized using spiked

soil and water samples. For the PSWE of the

organochlorine compounds, water modified with

acetonitrile as the extraction solvent, at an extraction

temperature of 120 degrees C, and three cycles of 10 min

extraction proved to be optimal. Under optimized

conditions, the figures of merit, such as precision,

accuracy and detection limits were evaluated. The

detection limits obtained for soil samples were in the

range 0.002-4.7 ng/g. Recoveries between 4.1 and 85.2%

were achieved from samples spiked at a concentration

level of 25-155 ng/g. The main advantages of this method

are the avoidance of clean-up and concentration

procedures as well as the significant reduction of the

required volume of organic solvents. The described

method was applied to the determination of the

pollutants in soil samples collected from a polluted

area, the Bitterfeld region (Germany). The results

obtained by PSWE-SBSE were in a good agreement with

those obtained by a reference method, a conventional

pressurized liquid extraction (PLE).

Efficient decomposition of environmentally persistent

perfluorooctanesulfonate and related fluorochemicals

using zerovalent iron in subcritical water.

Decomposition of perfluorooctanesulfonate (PFOS) and

related chemicals in subcritical water was investigated.

Although PFOS demonstrated little reactivity in pure

subcritical water, addition of zerovalent metals to the

reaction system enhanced the PFOS decomposition to form

F-ions, with an increasing order of activity of no metal

approximately equal Al < Cu < Zn << Fe. Use of iron led

to the most efficient PFOS decomposition: When iron

powder was added to an aqueous solution of PFOS (93-372

microM) and the mixture was heated at 350 degrees C for

6 h, PFOS concentration in the reaction solution fell

below 2.2 microM (detection limit of HPLC with

conductometric detection), with formation of F-ions with

yields [i.e., (moles of F- formed)/(moles of fluorine

content in initial PFOS) x 100] of 46.2-51.4% and

without any formation of perfluorocarboxylic acids. A

small amount of CHF3 was detected in the gas phase with

a yield [i.e., (moles of CHF3)/(moles of carbon content

in initial PFOS) x 100] of 0.7%, after the reaction of

PFOS (372 microM) with iron at 350 degree C for 6 h.

Spectroscopic measurements indicated that PFOS in water

markedly adsorbed on the iron surface even at room

temperature, and the adsorbed fluorinated species on the

iron surface decomposed with rising temperature, with

prominent release of F- ions to the solution phase above

250 degrees C. This method was also effective in

decomposing other perfluoroalkylsulfonates bearing

shorter chain (C2-C6) perfluoroalkyl groups and was

successfully applied to the decomposition of PFOS

contained in an antireflective coating agent used in

semiconductor manufacturing.

Resource recovery from excess sludge by subcritical

water combined with magnesium ammonium phosphate

process.

The amount

of excess sludge produced in municipal wastewater

treatment plants in Japan is increasing every year as

the urban population increases. Phosphorus in excess

sludge could be a potential phosphorus resource since at

present, phosphate rock is being exhausted all over the

world. Every year, Japan imports large quantities of

phosphorus from abroad but much is discharged as excess

sludge. Therefore, the solubilization process, one

method of recovering phosphorus from sludge, could be a

promising solution. In this study, a subcritical water

process, a new technology that solubilizes sludge under

subcritical conditions, was applied before the

phosphorus in sludge was recovered with the magnesium

ammonium phosphate (MAP) process. As a result, the

solubilization rate of excess sludge achieved

approximately 80% and about 94-97% of the phosphorus

could be recovered.

Rapid determination of inorganic elements in airborne

particulate matter by using acidified subcritical-water

extraction and inductively-coupled

plasma-optical-emission spectrometry.

A rapid and

simple method has been developed for determination of

inorganic elements in airborne particulate matter (PM10)

by using acidified subcritical water and ICP-OES.

Elements such as Al, As, B, Ba, Cd, Cu, Fe, Mn, Pb, Se,

and Zn were rapidly and efficiently extracted from PM10

samples with a solution of 0.1 mol L(-1) HNO(3) under

subcritical conditions. The method requires

approximately 5% of the amount of acid used in the

standard microwave extraction procedure. The material

selected for the subcritical extraction manifold was

poly ether ether ketone (PEEK), to avoid sample

contamination with elements present in previously

reported stainless-steel manifolds. The extraction

temperature, time of static and dynamic extraction, and

flow rate of acidified water were studied keeping the

pressure controlled at about 1,500 psig. The efficiency

of extraction of most of the analytes increased with

temperature, tending to quantitative extraction at

temperatures near 150 degrees C. After the extraction

process the analytes were determined directly in the

extract by ICP-OES. When the method was compared with

the USEPA counterpart, the results indicate that under

optimized conditions (static extraction time: 15 min,

dynamic extraction time: 30 min, flow rate: 2 mL

min(-1)) the analytes were extracted with recoveries

between 73 and 158%. Alternatively, by using an

extraction time of 15 min, the method could be used to

screen for all the elements, with recoveries over 50%.

The developed method was applied to the determination of

inorganic elements in airborne particulate matter in the

atmosphere of Santiago, Chile.

Decomposition kinetics of maltose in subcritical water.

The

decomposition process of maltose in subcritical water

was studied using a tubular reactor in the temperature

range of 180 to 260 degrees C and at 10 MPa. The

formation of glucose and 5-hydroxymethyl-2-furaldehyde

during the maltose decomposition was also observed. The

decomposition rate of maltose was faster at higher

temperatures. The rate was approximated by first-order

kinetics during the early stage of the decomposition,

but was accelerated and deviated from these kinetics at

the later stage. The effluent pH decreased as the

residence time in the reactor increased and the decrease

of pH affected the maltose decomposition rate and

glucose formation. Low pH of a feed solution accelerated

maltose decomposition. A good correlation was obtained

between the pH of the effluent and the rate constant of

the first-order kinetics.

Hydrolysis of ginger bagasse starch in subcritical water

and carbon dioxide.

Ginger

bagasse from supercritical extraction was hydrolyzed

using subcritical water and CO(2) to produce reducing

sugars and other low molecular mass substances. Response

surface methodology was used to find the best hydrolysis

conditions; the degree of hydrolysis and the yield were

the two response variables selected for maximization.

The kinetic studies of the hydrolysis were performed at

150 bar and temperatures of 176, 188, and 200 degrees C.

The higher degree of hydrolysis (97.1% after 15 min of

reaction) and higher reducing sugars yield (18.1% after

11 min of reaction) were established for the higher

process temperature (200 degrees C). Different mixtures

of oligosaccharides with different molecular mass

distributions were obtained, depending on the

temperature and on the reaction time. The ginger bagasse

hydrolysis was treated as a heterogeneous reaction with

a first-order global chemical kinetic, in relation to

the starch concentration, which resulted in an

activation energy of 180.2 kJ/mol and a preexponential

factor of 5.79 x 10(17)/s.

Subcritical (hot/liquid) water dechlorination of PCBs (Aroclor

1254) with metal additives and in waste paint.

No disposal

option exists for "mixed wastes" such as paint scrapings

that are co-contaminated with polychlorinated biphenyls

(PCBs) and radioactive metals. Either removal or

destruction of the PCBs is required prior to disposal.

Comparison of subcritical water dechlorination (350

degrees C, 1 h) of Aroclor 1254 in paint scrapings (180

ppm) and of standard Aroclor 1254 showed significantly

enhanced dechlorination in the presence of paint. While

no significant degradation was observed for standard

Aroclor (no paint), the dechlorination of PCBs in paint

was 99, 99, and 80% for the hepta-, hexa-, and

pentachlorinated congeners, respectively, indicating

that metals in the paint enhanced the dechlorination

reactions. Adding metals to the standard Aroclor (no

paint) reactions enhanced PCB dechlorination in

subcritical water in descending order of activity: Pb

approximately = Cu > Al > Zn > Fe. In the presence of

both zerovalent and divalent lead and zerovalent copper

in subcritical water (350 degrees C, 1 h), 99% of the

Aroclor 1254 mixture (tetra- to heptachlorinated

biphenyls) was dechlorinated. High dechlorination (ca.

95%) was also achieved with zerovalent aluminum. In

contrast to other metals, lead retained its degradation

ability at a lower temperature of 250 degrees C after 18

h. The high degradation efficiency achieved using metal

additives in water at reasonable temperatures and

pressures demonstrates the potential for subcritical

water dechlorination of PCBs in paint scrapings and,

potentially, in other solid and liquid wastes.

Off-line coupling of subcritical water extraction with

subcritical water chromatography via a sorbent trap and

thermal desorption.

In this

study, the off-line coupling of subcritical water

extraction (SBWE) with subcritical water chromatography

(SBWC) was achieved using a sorbent trap and thermal

desorption. The sorbent trap was employed to collect the

extracted analytes during subcritical water extraction.

After the extraction, the trap was connected to the

subcritical water chromatography system, and thermal

desorption of the trapped analytes was performed before

the SBWC run. The thermally desorbed analytes were then

introduced into the subcritical water separation column

and detected by a UV detector. Anilines and phenols were

extracted from sand and analyzed using this off-line

coupling technique. Subcritical water extraction of

flavones from orange peel followed by subcritical water

chromatographic separation was also investigated. The

effects of water volume and extraction temperature on

flavone recovery were determined. Because a sorbent trap

was used to collect the extracted analytes, the

sensitivity of this technique was greatly enhanced as

compared to that of subcritical water extraction with

solvent trapping. Since no organic solvent-water

extractions were necessary prior to analysis, this

technique eliminated any use of organic solvents in both

extraction and chromatography processes.

Subcritical water extraction of antioxidant compounds

from rosemary plants.

Subcritical water extraction at several

temperatures ranging from 25 to 200 degrees C has been

studied to selectively extract antioxidant compounds

from rosemary leaves. An exhaustive characterization of

the fractions obtained using subcritical water at

different temperatures has been carried out by LC-MS,

and the antioxidant activities of the extracts have been

measured by a free radical method (DPPH). Results

indicate high selectivity of the subcritical water

toward the most active compounds of rosemary such as

carnosol, rosmanol, carnosic acid, methyl carnosate, and

some flavonoids such as cirsimaritin and genkwanin. The

antioxidant activity of the fractions obtained by

extraction at different water temperatures was very

high, with values around 11.3 microg/mL, comparable to

those achieved by SFE of rosemary leaves. A study of the

effect of the temperature on the extraction efficiency

of the most typical rosemary antioxidant compounds has

been performed.

Alkaline subcritical-water treatment and alkaline heat

treatment for the increase in biodegradability of

newsprint waste.

This work

describes two alkaline semicontinuous processes for the

conversion of refractory organic materials into

biodegradable substances. Newsprint was used as a

lignocellulosic waste. Methane conversion efficiencies

and cellulose removals were investigated for the two

following processes: alkaline subcritical-water

treatment (ASWT) coupled with methane fermentation and

alkaline heat treatment (newsprint heated with steam in

an autoclave; AHT) coupled with methane fermentation

with a neutral subcritical-water treatment (NSWT)

recycle. Results showed that for ASWT coupled with

methane fermentation higher methane conversion

efficiencies and higher cellulose removals were achieved

as HRT increased. At HRT = 20 days, average CH4

conversion efficiency and average cellulose removal

reached 26% and 44%, respectively. After a final HRT of

40 days, average CH4 conversion efficiency and average

cellulose removal reached 50% and 60%, respectively. On

the other hand, for AHT coupled with methane

fermentation, methane conversion efficiencies did not

show a greater improvement using this pretreatment

process. Average conversion reached 9% with an average

cellulose removal of 20%. In order to improve the yield

of the reactor, approximately one-third of the effluent

was recycled using NSWT (150 degrees C; neutral pH).

Methane conversion efficiency of this process increased

as more recycles were performed. For the fifth

operation, the total average methane conversion

efficiency was 44% with a total average cellulose

removal of 55%.

A novel process utilizing subcritical water and

nitrilotriacetic acid to extract hazardous elements from

MSW incinerator fly ash.

An

effective process for hazardous element extraction from

municipal solid waste incinerator fly ash was developed.

The key trait of the process was to extract most of the

hazardous elements out of the ash but leave Ca and Si

inside the residue. In the extraction process, the ash

was firstly pre-washed with water, then subjected to

subcritical water (SC water) treatment and

nitrilotriacetic acid (NTA) extraction. SEM images

indicated that SC water is strong enough to destroy the

ash particles, thus greatly improving hazardous elements

extraction efficiency in the subsequent NTA extraction

process. The extraction percentages for Cr, As, Se, Cd

and Pb under SC water+NTA treatment were around 2-6

times higher than those treated by NTA at room

conditions. The preferable SC treatment temperature was

573 K and the treatment time was 3 h. The optimum NTA

concentration, vibration time and liquid/solid ratio

were 0.8 M, 5 h and 10:1 (ml/g), respectively.

Furthermore, it was found that introduction of a

suitable amount of sulfuric acid into the extraction

solution could extract more than 90% of most of the

hazardous elements out of the ash.

Reductive dechlorination of polychlorinated dibenzo-p-dioxins

by zerovalent iron in subcritical water.

A new

method for reductive dechlorination of polychlorinated

dibenzo-p-dioxins (PCDDs) and remediation of

contaminated soils is described that uses zerovalent

iron as the dechlorination agent and subcritical water

as reaction medium and extractive solvent. It is found

that the zerovalent iron can be applied for stepwise

dechlorination of octachlorinated dibenzo-p-dioxin (OCDD)

on various matrixes in subcritical water. By using iron

powder as matrix higher chlorinated congeners were

practically completely reduced to less than

tetra-substituted homologues. A significant part of

residual OCDD, when it was spiked in to soils, and

formed less chlorinated congeners are extracted with

water in the given conditions. The solubility of OCDD

was increased by a 4-6 orders over its solubility at

ambient conditions. The new method of contentious-flow

extraction is described.

Subcritical water extraction and determination of

nifedipine in pharmaceutical formulations.

A rapid and

simple continuous method for the extraction of

nifedipine from tablets was developed by using

pressurized hot water at 150 degrees C. This is the

first time that subcritical water was applied to the

extraction of low-polarity compounds in pharmaceutical

analysis. The method is based on the increment in

solubility of nifedipine in subcritical water.

Extraction temperature and static and dynamic extraction

time were optimized in order to reach quantitative

extraction of the drug from the tablets. After

extraction, the drug was determined by spectrophotometry

by measuring absorbance at 338 nm. Accuracy and

precision of the method were determined by analysis of

10 synthetic samples of pharmaceutical formulations

prepared with common tablet excipients. Recovery was

found to be 99.2% with a relative standard deviation of

1.9%, which indicates that the excipients of the

formulation do not interfere in the determination. The

method was applied to the determination of the drug

content uniformity in tablets.

Subcritical water extraction of essential oils from

coriander seeds (Coriandrum sativum L.)

Subcritical water extraction (SCWE),

hydrodistillation and Soxhlet extraction were compared

for the extraction of essential oil from coriander seeds

(Coriandrum sativum L.). The extraction

efficiencies of different temperatures (100, 125, 150

and 175 °C), mean particle sizes (0.25, 0.50 and 1 mm),

and water flow rates (1, 2 and 4 ml/min) were

investigated. Separation and identification of the

components were carried out by GC–FID and GC–MS. The

results showed that the optimum temperature, mean

particle size, and flow rate were 125 °C, 0.5 mm, and

2 ml/min. The SCWE was compared with both conventional

methods in terms of the efficiency and the essential oil

composition. Hydrodistillation and Soxhlet extraction

showed higher extraction efficiencies, but the SCWE

resulted to the essential oils more concentrated in

valuable oxygenated components.

Ethanol-modified subcritical water extraction combined

with solid-phase microextraction for determining

atrazine in beef kidney.

The

determination of the levels of pesticides in food

products has prompted the development of sensitive and

rapid methods of analysis that are solvent-free or

utilize solvents that are benign to the environment and

laboratory worker. In this study we have developed a

novel extraction method that utilizes ethanol-modified

subcritical water in combination with solid-phase

microextraction (SPME) for the removal of atrazine from

beef kidney. In situ sample cleanup was achieved using

the technique of matrix solid-phase dispersion. A

cross-linked polymer, XAD-7 HP, was utilized as a

dispersing material for kidney samples. Subcritical

water extractions were performed with a pressurized

solvent extraction unit at 100 degrees C and 50 atm.

Experimental parameters investigated were the volume of

solvent and amount of modifier required for the complete

extraction of atrazine and optimization of the

extraction time. It was determined that 30% ethanol in

water (v/v) is adequate for the complete extraction of

atrazine. A Carbowax-divinylbenzene SPME fiber was used

to sample the aqueous extracts. Analysis of the fiber

contents was by ion-trap GC/MS utilizing the single ion

mode. The total time of analysis for a single kidney

sample is 90 min. The average percent recoveries from

samples spiked to the concentrations of 2 and 0.2 microg/g

were 104 and 111, respectively. The average relative

standard deviations were 10 and 9, respectively. The

method limit of detection for beef kidney spiked with

atrazine was found to be 20 ng/g of sample.

Extraction of tricyclazole from soil and sediment with

subcritical water.

The use of

subcritical water to extract tricyclazole from soils and

sediments was examined. Extraction efficiency and

kinetics were determined as a function of temperature,

sample age, sample matrix, sample size, and flow rate.

Extraction temperature was the most influential

experimental factor affecting extraction efficiency and

kinetics, with increasing temperature (up to 150 degrees

C) yielding faster and higher efficiency extractions.

Higher extraction temperatures were also important for

quantitative recovery of tricyclazole from aged samples.

Extraction at 50 degrees C yielded 97% recoveries from

samples aged 1 day but only 30% recoveries for samples

aged 202 days, whereas extraction at 150 degrees C

yielded recoveries of 85-100% that were independent of

incubation time and sample matrix, with the exception of

one sediment that contained a large amount of organic

matter. Sample extracts from subcritical water

extraction were generally a pale yellow color,

contrasted with a dark brown color from organic solvent

extractions of the same matrixes. Less sample cleanup

was therefore required prior to analysis, with the total

time for the extraction and analysis of a single sample

being approximately 2 h. Subcritical water extraction is

an effective technique for the rapid and quantitative

extraction of tricyclazole from soils and sediments.

Continuous subcritical water extraction of medicinal

plant essential oil: comparison with conventional

techniques

A

subcritical extractor equipped with a three-way inlet

valve and an on/off outlet valve has been used for

performing subcritical water extractions (SWE) in a

continuous manner for the isolation of the essential oil

of fennel, a medicinal plant. The target compounds were

removed from the aqueous extract by a single extraction

with 5 ml hexane, determined by gas-chromatography-flame

ionization (GC-FID) and identified by mass spectrometry

(MS). The proposed extraction method has been compared

with both hydrodistillation and dichloromethane manual

extraction. Better results have been obtained with the

proposed method in terms of rapidity, efficiency,

cleanliness and possibility of manipulating the

composition of the extract.

Characteristics of lithium iron phosphate (LiFePO4)

particles synthesized in subcritical and supercritical

water

The effect

of temperature, pH, time, and reactant concentrations on

the size and morphology of lithium iron phosphate

(LiFePO4) particles synthesized in a batch

hydrothermal reactor was investigated in this work. It

was found that LiFePO4 could only be

synthesized at neutral or slightly basic pH in both

subcritical and supercritical water. Synthesis in

subcritical water resulted in micron-sized particles of

high crystallinity, whereas synthesis in supercritical

water produced submicron particles. A more uniform

particle size distribution was obtained at low reactant

concentrations, irrespective of the synthesis

temperature. Qualitative explanations for these

observations are provided in terms of nucleation,

growth, and agglomeration phenomena at subcritical and

supercritical conditions.

Results of Search in US Patent

Collection db for:

"Subcritical": patents.

| |

PAT. NO. |

|

Title |

| 1 |

7,387,761 |

|

Method for

manufacturing a glass infiltrated metal oxide

infrastructure

|

| 2 |

7,386,985 |

|

Detection of

refrigerant charge adequacy based on multiple

temperature measurements

|

| 3 |

7,385,057 |

|

Method and

device for producing melamine in a single-phase

tubular reactor

|

| 4 |

7,384,484 |

|

Substrate

processing method, substrate processing

apparatus and substrate processing system

|

| 5 |

7,381,439 |

|

Method and

composition for washing poultry during

processing

|

| 6 |

7,381,320 |

|

Heavy oil

and bitumen upgrading

|

| 7 |

7,381,278 |

|

Using

supercritical fluids to clean lenses and monitor

defects |

| 8 |

7,374,900 |

|

Fluorescent

substrates for detecting organophosphatase

enzyme activity

|

| 9 |

7,365,236 |

|

Generation

of a creosote-like mixture, or recovery of

metals, or both from preserved wood by reaction

in supercritical water

|

| 10 |

7,365,234 |

|

Tuning

product selectivity in catalytic

hydroformylation reactions with carbon dioxide

expanded liquids

|

| 11 |

7,364,839 |

|

Method for

forming a pattern and substrate-processing

apparatus |

| 12 |

7,361,231 |

|

System and

method for mid-pressure dense phase gas and

ultrasonic cleaning

|

| 13 |

7,360,420 |

|

Method and

bearing for balancing rotors without journals

|

| 14 |

7,353,113 |

|

System,

method and computer program product for aquatic

environment assessment

|

| 15 |

7,349,517 |

|

System for

measuring burn-out of fuel elements of a

high-temperature reactor

|

| 16 |

7,347,193 |

|

Method and

device for determining the mass flow rate

passing through the air-bleed valve of an

internal combustion engine tank

|

| 17 |

7,344,746 |

|

Process for

the hydrogenation of hop resin acids

|

| 18 |

7,337,742 |

|

Twin fin

fairing |

| 19 |

7,337,356 |

|

Systematic

and random error detection and recovery within

processing stages of an integrated circuit

|

| 20 |

7,335,296 |

|

System and

device for processing supercritical and

subcritical fluid

|

| 21 |

7,335,287 |

|

Solid

electrolyte sensor for monitoring the

concentration of an element in a fluid

particularly molten metal

|

| 22 |

7,334,430 |

|

Refrigerating cycle

|

| 23 |

7,331,313 |

|

Continuous

steam generator with circulating atmospheric

fluidised-bed combustion

|

| 24 |

7,326,756 |

|

High

temperature bulk polymerization of branched

crystalline polypropylene

|

| 25 |

7,326,337 |

|

System for

oxidation of organic bodies present in an

aqueous effluent

|

| 26 |

7,326,001 |

|

Wave forming

apparatus and method

|

| 27 |

7,323,096 |

|

Method for

treating the surface of object and apparatus

thereof |

| 28 |

7,322,101 |

|

Turbine

engine disk spacers

|

| 29 |

7,320,229 |

|

Ejector

refrigeration cycle

|

| 30 |

7,320,091 |

|

Error

recovery within processing stages of an

integrated circuit

|

| 31 |

7,319,125 |

|

Supercritical polymerization process and

polymers produced therefrom

|

| 32 |

7,316,824 |

|

Method and

composition for washing poultry during

processing

|

| 33 |

7,316,769 |

|

Length-dependent recoil separation of long

molecules |

| 34 |

7,314,942 |

|

Methylenelactones syntheses in supercritical

fluids |

| 35 |

7,311,003 |

|

Method and

device for balancing journal-less rotors

|

| 36 |

7,310,755 |

|

Data

retention latch provision within integrated

circuits |

| 37 |

7,304,309 |

|

Radiation

detectors |

| 38 |

7,300,527 |

|

Method for

activating surface of base material and

apparatus thereof

|

| 39 |

7,299,913 |

|

Drive unit

for a vibrating spiral conveyor

|

| 40 |

7,294,353 |

|

Methods and

compositions comprising ilex

|

| 41 |

7,293,403 |

|

Combustion

chamber with internal jacket made of a ceramic

composite material and process for manufacture

|

| 42 |

7,291,890 |

|

Gate

dielectric and method

|

| 43 |

7,291,296 |

|

Method for

making very fine particles consisting of a

principle inserted in a host molecule

|

| 44 |

7,288,237 |

|

Epoxidation

catalyst |

| 45 |

7,287,725 |

|

Missile

control system and method

|

| 46 |

7,287,541 |

|

Method,

apparatus and system for controlling fluid flow

|

| 47 |

7,287,381 |

|

Power

recovery and energy conversion systems and

methods of using same

|

| 48 |

7,285,312 |

|

Atomic layer

deposition for turbine components

|

| 49 |

7,282,099 |

|

Dense phase

processing fluids for microelectronic component

manufacture

|

| 50 |

7,281,484 |

|

Multimission

transonic hull and hydrofield

|

| 51 |

7,279,184 |

|

Methods and

compositions comprising Ilex

|

| 52 |

7,279,127 |

|

Continuous

steelmaking plant

|

| 53 |

7,278,264 |

|

Process to

convert low grade heat source into power using

dense fluid expander

|

| 54 |

7,276,184 |

|

Surfactant

assisted nanomaterial generation process

|

| 55 |

7,275,400 |

|

Washing

apparatus |

| 56 |

7,273,826 |

|

Epoxidation

catalyst |

| 57 |

7,270,795 |

|

Method for

producing nano-carbon materials

|

| 58 |

7,267,727 |

|

Processing

of semiconductor components with dense

processing fluids and ultrasonic energy

|

| 59 |

7,264,710 |

|

Process and

apparatus for treating heavy oil with

supercritical water and power generation system

equipped with heavy oil treating apparatus

|

| 60 |

7,263,727 |

|

Hygienic

high detergency toilet

|

| 61 |

7,262,422 |

|

Use of

supercritical fluid to dry wafer and clean lens

in immersion lithography

|

| 62 |

7,261,529 |

|

Apparatus

for preparing biodegradable microparticle

formulations containing pharmaceutically active

agents |

| 63 |

7,260,001 |

|

Memory

system having fast and slow data reading

mechanisms

|

| 64 |

7,259,231 |

|

Extraction

and fractionation of biopolymers and resins from

plant materials

|

| 65 |

7,259,136 |

|

Compositions

and methods for treating peripheral vascular

disease |

| 66 |

7,258,791 |

|

Method of

reducing volume of sludge

|

| 67 |

7,252,719 |

|

High

pressure processing method

|

| 68 |

7,244,461 |

|

Method of

preparing liquid smoke

|

| 69 |

7,243,618 |

|

Steam

generator with hybrid circulation

|

| 70 |

7,243,501 |

|

Expansion

device for an air-conditioning system

|

| 71 |

7,238,833 |

|

Production

of aromatic carboxylic acids

|

| 72 |

7,237,574 |

|

Controlled

dispersion multi-phase nozzle and method of

making the same

|

| 73 |

7,235,421 |

|

System and

method for developing production nano-material

|

| 74 |

7,235,224 |

|

Process for

preparing fine metal oxide particles

|

| 75 |

7,232,053 |

|

Seam-welded

air hardenable steel constructions

|

| 76 |

7,229,979 |

|

Hypoestoxides, derivatives and agonists thereof

for use as stent-coating agents

|

| 77 |

7,226,771 |

|

Phospholipases, nucleic acids encoding them and

methods for making and using them

|

| 78 |

7,217,750 |

|

Process for

incorporating one or more materials into a

polymer composition and products produced

thereby |

| 79 |

7,216,830 |

|

Wing gull

integration nacelle clearance, compact landing

gear stowage, and sonic boom reduction

|

| 80 |

7,216,498 |

|

Method and

apparatus for determining supercritical pressure

in a heat exchanger

|

| 81 |

7,216,427 |

|

Surface

treatment of prefinished valve seat inserts

|

| 82 |

7,214,394 |

|

Policosanol

compositions, extraction from novel sources, and

uses thereof

|

| 83 |

7,211,553 |

|

Processing

of substrates with dense fluids comprising

acetylenic diols and/or alcohols

|

| 84 |

7,211,145 |

|

Substrate

processing apparatus and substrate processing

method |

| 85 |

7,208,181 |

|

Isolation of

polyphenolic compounds from fruits or vegetables

utilizing sub-critical water extraction

|

| 86 |

7,201,804 |

|

Cleaning of

hydrocarbon-containing materials with critical

and supercritical solents

|

| 87 |

7,201,019 |

|

Light gas

component separation from a carbon dioxide

mixture |

| 88 |

7,197,876 |

|

System and

apparatus for power system utilizing wide

temperature range heat sources

|

| 89 |

7,197,404 |

|

Computation

of radiating particle and wave distributions

using a generalized discrete field constructed

from representative ray sets

|

| 90 |

7,195,676 |

|

Method for

removal of flux and other residue in dense fluid

systems |

| 91 |

7,193,120 |

|

Colloid-catalyzed gas transfer in supercritical

phases |

| 92 |

7,193,097 |

|

Method of

producing a fatty acid ester

|

| 93 |

7,192,995 |

|

Homogenous

compositions of polymers and crystalline solids

or cross-linking agents and methods of making

the same |

| 94 |

7,192,217 |

|

Baffle

apparatus |

| 95 |

7,189,350 |

|

Method of

sterilizing medical instruments

|

| 96 |

7,189,196 |

|

Method of

separating materials with a concentric tubular

centrifuge

|

| 97 |

7,183,229 |

|

Semiconductor thin film forming method,

production methods for semiconductor device and

electrooptical device, devices used for these

methods, and semiconductor device and

electrooptical device

|

| 98 |

7,182,861 |

|

System for

separating electrophotographic carrier

compositions and recycling the compositions

|

| 99 |

7,181,862 |

|

Sol-gel

process for the production of glassy articles

|

| 100 |

7,178,362 |

|

Expansion

device arrangement for vapor compression system

|

| 101 |

7,175,886 |

|

Apparatus and method

for micron and submicron particle formation

|

| 102 |

7,174,713 |

|

Method for

determination of composition of the gas mixture in a combustion chamber

of an internal combustion engine with exhaust gas recirculation and

correspondingly configured control system for an internal combustion

engine |

| 103 |

7,169,857 |

|

Homogenous

compositions of fluoropolymers and crystalline solids or cross-linking

agents and methods of making the same

|

| 104 |

7,169,179 |

|

Drug delivery device

and method for bi-directional drug delivery

|

| 105 |

7,166,753 |

|

Process for

production of hydrogen and carbonyl compounds by reacting sub- or

super-critical water with alcohols

|

| 106 |

7,166,658 |

|

Rubber reduction

|

| 107 |

7,164,197 |

|

Dielectric composite

material |

| 108 |

7,163,989 |

|

Processes and

apparatus for continuous solution polymerization

|

| 109 |

7,162,661 |

|

Systematic and random

error detection and recovery within processing stages of an integrated

circuit |

| 110 |

7,160,492 |

|

Orthopaedic device

for implantation in the body of an animal and method for making the same

|

| 111 |

7,160,380 |

|

Organic pigment

fine-particle, and method of producing the same

|

| 112 |

7,159,409 |

|

Method and apparatus

for controlling the load placed on a compressor

|

| 113 |

7,157,886 |

|

Power converter

method and apparatus having high input power factor and low harmonic

distortion |

| 114 |

7,157,534 |

|

Polymerization

process for producing copolymers |

| 115 |

7,157,002 |

|

Process for the

recovery of surfactants |

| 116 |

7,156,925 |

|

Using supercritical

fluids to clean lenses and monitor defects

|

| 117 |

7,148,387 |

|

Process for producing

hydroxyl group-containing compound

|

| 118 |

7,147,670 |

|

Cleaning system

utilizing an organic cleaning solvent and a pressurized fluid solvent

|

| 119 |

7,147,436 |

|

Turbine engine rotor

retainer |

| 120 |

7,144,498 |

|

Supercritical

hydrocarbon conversion process |

| 121 |

7,144,461 |

|

Method of removing

acid component in deteriorated acetate film

|

| 122 |

7,140,197 |

|

Means and apparatus

for microrefrigeration |

| 123 |

7,131,294 |

|

Method and apparatus

for control of carbon dioxide gas cooler pressure by use of a capillary

tube |

| 124 |

7,131,291 |

|

Compression system

for cooling and heating purposes |

| 125 |

7,131,259 |

|

High density combined

cycle power plant process |

| 126 |

7,129,200 |

|

Domestic fabric

article refreshment in integrated cleaning and treatment processes

|

| 127 |

7,127,905 |

|

Vapor compression

system startup method |

| 128 |

7,118,696 |

|

Method of forming

light dispersing fiber and fiber formed thereby

|

| 129 |

7,114,508 |

|

Cleaning apparatus

having multiple wash tanks for carbon dioxide dry cleaning and methods

of using same |

| 130 |

7,111,630 |

|

High pressure

processing apparatus and method |

| 131 |

7,108,867 |

|

Process for preparing

particles |

| 132 |

7,108,223 |

|

Missile control

system and method |

| 133 |

7,105,185 |

|

Kavalactone profile

|

| 134 |

7,101,499 |

|

Method of and

apparatus for producing pellets from heavy hydrocarbon liquid

|

| 135 |

7,097,715 |

|

Cleaning system

utilizing an organic cleaning solvent and a pressurized fluid solvent

|

| 136 |

7,096,679 |

|

Transcritical vapor

compression system and method of operating including refrigerant storage

tank and non-variable expansion device

|

| 137 |

7,091,366 |

|

Recovery of residual

specialty oil |

| 138 |

7,091,288 |

|

Polymerization of

vinylidene fluoride (VF.sub.2) in a supercritical fluid medium

|

| 139 |

7,090,871 |

|

Composition

containing pyrrolizidine-alkaloid-free petasites

|

| 140 |

7,084,269 |

|

Process for producing

lactam |

| 141 |

7,084,181 |

|

Method for

decomposing nonmetallic honeycomb panel, and method for recycling the

same |

| 142 |

7,082,355 |

|

Wake wash severity

monitor for high speed vessels |

| 143 |

7,081,486 |

|

Method of producing

polymer |

| 144 |

7,081,133 |

|

Antibiotic treated

implantable medical devices |

| 145 |

7,080,651 |

|

High pressure

processing apparatus and method |

| 146 |

7,078,731 |

|

Gallium nitride

crystals and wafers and method of making

|

| 147 |

7,078,359 |

|

Aerogel composite

with fibrous batting |

| 148 |

RE39,171 |

|

Simulated wave water

sculpture |

| 149 |

7,074,881 |

|

Methods of synthesis

of polysuccinimide, copolymers of polysuccinimide and derivatives

thereof |

| 150 |

7,074,369 |

|

Method and apparatus

for decoupled thermo-catalytic pollution control |

| 151 |

7,072,229 |

|

Memory system having

fast and slow data reading mechanisms

|

| 152 |

7,070,146 |

|

Aircraft

thickness/camber control device for low sonic boom

|

| 153 |

7,067,640 |

|

Cross-linked chiral

compounds and methods of making thereof

|

| 154 |

7,064,834 |

|

Method for analyzing

impurities in carbon dioxide |

| 155 |

7,063,795 |

|

Method for starting

up a system for treating waste by hydrothermal oxidation

|

| 156 |

7,063,750 |

|

Domestic fabric

article refreshment in integrated cleaning and treatment processes

|

| 157 |

7,059,831 |

|

Turbine engine disk

spacers |

| 158 |

7,059,512 |

|

Solder alloy material

layer composition, electroconductive and adhesive composition, flux

material layer composition, solder ball transferring sheet, bump and

bump forming process, and semiconductor device

|

| 159 |

7,058,100 |

|

Systems and methods

for thermal management of diode-pumped solid-state lasers

|

| 160 |

7,057,055 |

|

Process for preparing

a deuterated or tritiated compound

|

| 161 |

7,056,887 |

|

Treatment of acute

coronary syndrome with GLP-1 |

| 162 |

7,049,475 |

|

Organic compound

decomposing method |

| 163 |

7,049,030 |

|

Battery

|

| 164 |

7,045,642 |

|

Process for preparing

a deuterated or tritiated compound

|

| 165 |

7,045,622 |

|

Process for producing

lactam |

| 166 |

7,039,565 |

|

Method and system for

developing a numerical dynamic sanitary sewer and storm water drainage

simulation model |

| 167 |

7,039,528 |

|

Method for detecting

leak before rupture in a pipeline |

| 168 |

7,038,000 |

|

Process for preparing

propylene copolymers |

| 169 |

7,037,524 |

|

Oral delivery of a

botanical |

| 170 |

7,037,420 |

|

Anodic oxidation

method and treatment apparatus thereof

|

| 171 |

7,034,092 |

|

Process for producing

bimodal polyethylene resins |

| 172 |

7,034,084 |

|

Process and apparatus

for the hydrogenation of polymers under supercritical conditions

|

| 173 |

7,033,985 |

|

Domestic fabric

article refreshment in integrated cleaning and treatment processes

|

| 174 |

7,033,068 |

|

Substrate processing

apparatus for processing substrates using dense phase gas and sonic

waves |

| 175 |

7,032,373 |

|

Device for cooling

coolant in a gas turbine and gas and steam turbine with said device

|

| 176 |

7,029,707 |

|

Method of producing a

processed kava product having an altered kavalactone distribution and

processed kava products produced using the same

|

| 177 |

7,028,494 |

|

Defrosting

methodology for heat pump water heating system

|

| 178 |

7,025,992 |

|

Pharmaceutical

formulations |

| 179 |

7,022,863 |

|

Production method of

pyrrolidone carboxylic acid and salt thereof

|

| 180 |

7,021,106 |

|

Apparatus and method

for forming internally ribbed or rifled tubes

|

| 181 |

7,018,902 |

|

Gate dielectric and

method |

| 182 |

7,009,215 |

|

Group III-nitride

based resonant cavity light emitting devices fabricated on single

crystal gallium nitride substrates

|

| 183 |

7,008,528 |

|

Process and system

for continuously extracting oil from solid or liquid oil bearing

material |

| 184 |

7,005,301 |

|

Piecewise uniform

conduction-like flow channels and method therefor

|

| 185 |

7,003,968 |

|

Motor vehicle

air-conditioning installation equipped with an electronic control device

|

| 186 |

7,001,620 |

|

Kavalactone product

|

| 187 |

7,001,581 |

|

Method for producing

nanocarbon materials |

| 188 |

7,000,870 |

|

Laminar flow wing for

transonic cruise |

| 189 |

7,000,653 |

|

High pressure

processing apparatus and high pressure processing method

|

| 190 |

7,000,413 |

|

Control of

refrigeration system to optimize coefficient of performance

|

| 191 |

6,989,123 |

|

Methods to produce

gel sheets |

| 192 |

6,978,638 |

|

Nitrogen rejection

from condensed natural gas |

| 193 |

6,977,767 |

|

Plasmonic

nanophotonics methods, materials, and apparatuses

|

| 194 |

6,977,520 |

|

Time-multiplexed

routing in a programmable logic device architecture

|

| 195 |

6,972,271 |

|

Supported catalyst

systems |

| 196 |

6,968,708 |

|

Refrigeration system

having variable speed fan |

| 197 |

6,966,874 |

|

Concentric tubular

centrifuge |

| 198 |

6,964,787 |

|

Method and system for

reducing microbial burden on a food product

|

| 199 |

6,964,168 |

|

Advanced heat

recovery and energy conversion systems for power generation and

pollution emissions reduction, and methods of using same

|

| 200 |

6,962,714 |

|

Critical fluid

antimicrobial compositions and their use and generation

|

| 201 |

6,962,629 |

|

Method for moving

contaminants from gases |

| 202 |

6,960,672 |

|

Processes for

producing alkyl ester of fatty acid

|

| 203 |

6,960,618 |

|

Preparation method

for rigid polyurethane foam |

| 204 |

6,958,123 |

|

Method for removing a

sacrificial material with a compressed fluid

|

| 205 |

6,958,122 |

|

High pressure and

high temperature reaction system |

| 206 |

6,956,140 |

|

Hydrothermal

hydrolysis of halogenated compounds

|

| 207 |

6,955,051 |

|

Steam generation

apparatus and methods |

| 208 |

6,953,564 |

|

Method for producing

fullerenes |

| 209 |

6,952,346 |

|

Etched open

microchannel spray cooling |

| 210 |

6,948,238 |

|

Method for

dissociating metals from metal compounds

|

| 211 |

6,946,150 |

|

Pharmaceutical

formulation |

| 212 |

6,944,067 |

|

Memory system having

fast and slow data reading mechanisms

|

| 213 |

6,943,461 |

|

All-weather energy

and water production via steam-enhanced vortex tower

|

| 214 |

6,941,854 |

|

Sliding pairing for

machine parts that are subjected to the action of highly pressurized and

high-temperature steam, preferably for piston-cylinder assemblies of

steam engines |

| 215 |

6,939,837 |

|

Non-immersive method

for treating or cleaning fabrics using a siloxane lipophilic fluid

|

| 216 |

6,939,651 |

|

Electrophotographic

photoconductor, and process cartridge and electrophotographic apparatus

using the same |

| 217 |

6,936,843 |

|

Fixture used to

prepare semiconductor specimens for film adhesion testing

|

| 218 |

6,936,292 |

|

Deodorized yellow

colorant of safflower |

| 219 |

6,935,592 |

|

Aircraft lift device

for low sonic boom |

| 220 |

6,932,541 |

|

Wave forming

apparatus and method |

| 221 |

6,931,372 |

|

Joint multiple

program coding for digital audio broadcasting and other applications

|

| 222 |

6,929,752 |

|

Method for treating

waste by hydrothermal oxidation |

| 223 |

6,924,407 |

|

Pressure-tuned solid

catalyzed heterogeneous chemical reactions

|

| 224 |

6,924,004 |

|

Apparatus and method

for synthesizing films and coatings by focused particle beam deposition

|

| 225 |

6,923,011 |

|

Multi-stage vapor

compression system with intermediate pressure vessel

|

| 226 |

6,921,820 |

|

Method for forming

cellulose |

| 227 |

6,921,420 |

|

Apparatus and methods

for conserving vapor in a carbon dioxide dry cleaning system

|

| 228 |

6,919,421 |

|

Methods of synthesis

of polysuccinimide, copolymers of polysuccinimide and derivatives

thereof |

| 229 |

6,913,779 |

|

Process for the

preparation of accelerated release formulations using compressed fluids

|

| 230 |

6,908,660 |

|

Shaped body made of

fiber-reinforced composites having a segmented covering layer, its

production and its use |

| 231 |

6,906,423 |

|

Mask used for

exposing a porous substrate |

| 232 |

6,905,556 |

|

Method and apparatus

for using surfactants in supercritical fluid processing of wafers

|

| 233 |

6,905,555 |

|

Methods for

transferring supercritical fluids in microelectronic and other

industrial processes |

| 234 |

6,903,181 |

|

Methods of synthesis

of polysuccinimide, copolymers of polysuccinimide and derivatives

thereof |

| 235 |

6,902,999 |

|

Pattern formation

method |

| 236 |

6,901,814 |

|

Fuselage pitot-static

tube |

| 237 |

6,898,951 |

|

Washing apparatus

|

| 238 |

6,898,941 |

|

Supercritical

pressure regulation of vapor compression system by regulation of

expansion machine flowrate |

| 239 |

6,898,936 |

|

Compression stripping

of flue gas with energy recovery |

| 240 |

6,893,995 |

|

Supported catalyst

systems |

| 241 |

6,890,660 |

|

Combustion chamber

with internal jacket made of a ceramic composite material and process

for manufacture |

| 242 |

6,887,992 |

|

3-cephem derivative

crystal |

| 243 |

6,887,971 |

|

Synthesis of

polysuccinimide and copoly(succinimide-aspartate) in a supercritical

fluid |

| 244 |

6,887,516 |

|

Method and apparatus

for applying a powder coating |

| 245 |

6,886,487 |

|

Thruster apparatus

and method for reducing fluid-induced motions of and stresses within an

offshore platform |

| 246 |

6,884,911 |

|

Material processing

by repeated solvent expansion-contraction

|

| 247 |

6,884,900 |

|

Method for producing

fatty acid alcohol ester |

| 248 |

6,884,737 |

|

Method and apparatus

for precursor delivery utilizing the melting point depression of solid

deposition precursors in the presence of supercritical fluids

|

| 249 |

6,881,800 |

|

Processes and

apparatus for continuous solution polymerization

|

| 250 |

6,881,700 |

|

Dealuminized catalyst

carrier, method of production, and method for hydrating C2 or C3 olefins

with water |

| 251 |

6,881,699 |

|

Method for producing

a dealuminized catalyst support |

| 252 |

6,880,560 |

|

Substrate processing

apparatus for processing substrates using dense phase gas and sonic

waves |

| 253 |

6,880,326 |

|

High regression rate

hybrid rocket propellants and method of selecting

|

| 254 |

6,878,466 |

|

Method for improving

the reliability of brittle materials through the creation of a threshold

strength |

| 255 |

6,874,513 |

|

High pressure

processing apparatus |

| 256 |

6,858,179 |

|

Process for producing

sterile water for injection from potable water

|

| 257 |

6,857,437 |

|

Automated dense phase

fluid cleaning system |

| 258 |

6,849,678 |

|

Polymerization,

compatibilized blending, and particle size control of powder coatings in

a supercritical fluid |

| 259 |

6,848,269 |

|

Process and apparatus

for the recovery of krypton and/or xenon

|

| 260 |

6,846,562 |

|

Method of forming

light dispersing fiber and fiber formed thereby

|

| 261 |

6,845,900 |

|

Methods for producing

weld joints having thermally enhanced heat-affected-zones with excellent

fracture toughness |

| 262 |

6,844,561 |

|

Rotating aperture

system |

| 263 |

6,843,193 |

|

Transonic hull and

hydrofield (part III) |

| 264 |

6,841,031 |

|

Substrate processing

apparatus equipping with high-pressure processing unit

|

| 265 |

6,828,292 |

|

Domestic fabric

article refreshment in integrated cleaning and treatment processes

|

| 266 |

6,825,588 |

|

Uninterruptible power

supply using a high speed cylinder flywheel

|

| 267 |

6,825,260 |

|

Nanoporous

interpenetrating organic-inorganic networks

|

| 268 |

6,823,880 |

|

High pressure

processing apparatus and high pressure processing method

|

| 269 |

6,821,554 |

|

Polyol-based method

for forming thin film aerogels on semiconductor substrates

|

| 270 |

6,821,485 |

|

Method and structure

for microfluidic flow guiding |

| 271 |

6,821,481 |

|

Continuous processing

method and continuous processing apparatus for liquid-form substance,

and liquid-form substance processed thereby

|

| 272 |

6,821,429 |

|

Method and device for

capturing fine particles by trapping in a solid mixture of carbon

dioxide snow type |

| 273 |

6,821,413 |

|

Method and apparatus

for continuous separation and reaction using supercritical fluid

|

| 274 |

6,818,072 |

|

High-strength

heat-resistant steel, process for producing the same, and process for

producing high-strength heat-resistant pipe

|

| 275 |

6,818,021 |

|

Domestic fabric

article refreshment in integrated cleaning and treatment processes

|

| 276 |

6,817,193 |

|

Method for operating

a refrigerant circuit, method for operating a motor vehicle driving

engine, and refrigerant circuit |

| 277 |

6,813,895 |

|

Supercritical

pressure regulation of vapor compression system by regulation of

adaptive control |

| 278 |

6,805,801 |

|

Method and apparatus

to remove additives and contaminants from a supercritical processing

solution |

| 279 |

6,801,593 |

|

Subcritical

reactivity measurement method |

| 280 |

6,800,773 |

|

Chemical process

|

| 281 |

6,800,316 |

|

Method for

fractionating cooking oil |

| 282 |

6,800,272 |

|

Process for the

preparation of ZSM-5 catalyst |

| 283 |

6,799,587 |

|

Apparatus for

contaminant removal using natural convection flow and changes in

solubility concentrations by temperature

|

| 284 |

6,797,738 |

|

Open pore

biodegradable matrices |

| 285 |

6,796,275 |

|

Method and apparatus

for calculating minimum valve lift for internal combustion engines

|

| 286 |

6,796,137 |

|

Air conditioning

system comprising an electronic control device

|

| 287 |

6,795,991 |

|

Apparatus for

conserving vapor in a carbon dioxide dry cleaning system

|

| 288 |

6,795,780 |

|

Fluid energy pulse

test system--transient, ramp, steady state tests

|

| 289 |

6,794,544 |

|

Method for the

preparation of tetrahydrobenzothiepines

|

| 290 |

6,794,522 |

|

Process for preparing

a deuterated or tritiated compound

|

| 291 |

6,793,975 |

|

Methods of chemical

vapor deposition and powder formation

|

| 292 |

6,793,793 |

|

Electrochemical

treating method such as electroplating and electrochemical reaction

device therefor |

| 293 |

6,792,759 |

|

High density combined

cycle power plant process |

| 294 |

6,790,790 |

|

High modulus filler

for low k materials |

| 295 |

6,790,707 |

|

Method of preparing a